Facing a litany of challenges, from high turnover and frontline leadership issues to yield loss, give away, mechanical failures, and more, our meat processing client turned to the team at POWERS to meet customer demand.

Project Overview

Performance Results

Background

Our client is a hamburger patty producer serving the foodservice and retail markets with fresh and frozen hamburger patties.

They specialize in grinding various combinations of primal cuts to produce patties of different shapes and sizes based on their customer specifications.

They operate two major production facilities and serve several well-known restaurant chains, grocery chains, and foodservice distributors.

Situation

The plant we focused on suffered excessive annual yield loss, averaging 3.8% compared to their sister facility, which operated at a yield loss of only 2.5%.

While the two plants had different equipment and operational constraints, Senior Management felt there was an opportunity for the underperforming plant to improve yield significantly.

The plant had also recently hired a new Director of Operations, Plant Manager, and Plant Superintendent.

These individuals were fresh in their roles and had not yet established a defined Management Operating System. As a result, their management meetings were poorly defined and ineffective.

In addition, because they only reported Key Performance Indicators (KPIs) sporadically, the team lacked confidence in their accuracy and importance and failed to take corrective actions.

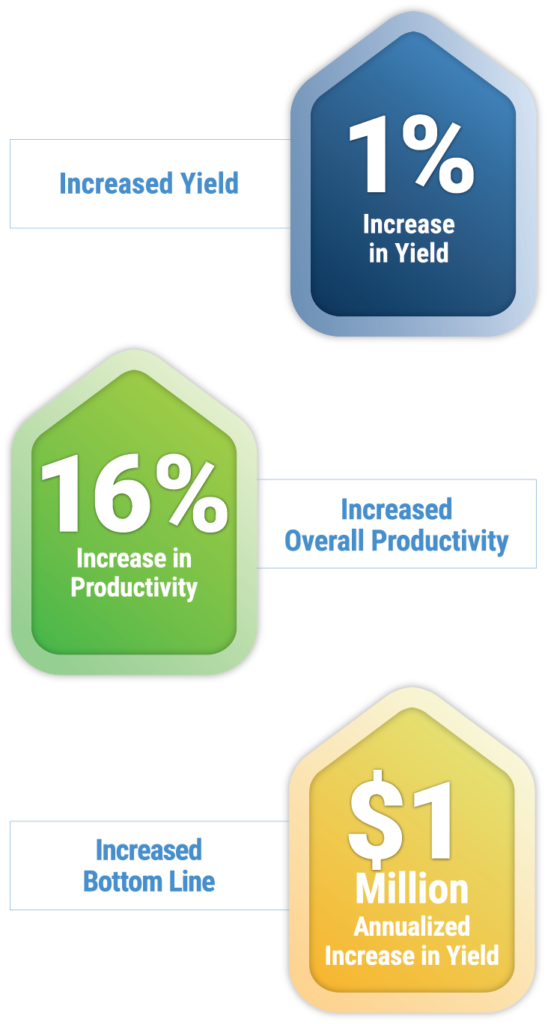

Meat Processor Grinds Out Beefy 1% Yield Increase and 16% Productivity Improvement With POWERS

Facing a litany of challenges, from high turnover and frontline leadership issues to yield loss, give away, mechanical failures, and more, our client turned to the team at POWERS to meet customer demand.

Background

Our client is a hamburger patty producer serving the foodservice and retail markets with fresh and frozen hamburger patties. They specialize in grinding various combinations of primal cuts to produce patties of different shapes and sizes based on their customer specifications.

They operate two major production facilities and serve several well-known restaurant chains, grocery chains, and foodservice distributors.

Situation

The plant we focused on suffered excessive annual yield loss, averaging 3.8% compared to their sister facility, which operated at a yield loss of only 2.5%. While the two plants had different equipment and operational constraints, Senior Management felt there was an opportunity for the underperforming plant to improve yield significantly.

The plant had also recently hired a new Director of Operations, Plant Manager, and Plant Superintendent. These individuals were fresh in their roles and had not yet established a defined Management Operating System. As a result, their management meetings were poorly defined and ineffective.

In addition, because they only reported Key Performance Indicators (KPIs) sporadically, the team lacked confidence in their accuracy and importance and failed to take corrective actions.

Analysis

Our team jumped in with frontline personnel and workers on the shop floor to uncover performance issues. In the first few weeks, through this immersive process, we constructed a process flow map identifying all possible loss points and revealing the business challenges.

Additionally, we conducted line observations, job shadowing, and an analysis of yield reporting. We found yield losses of 1% in blood loss at initial dumping stations, 1% yield loss in sanitation waste, 0.5% loss in bone separator waste, 0.8% in packaging giveaway, and 0.5% yield loss due to the miss-scanning of inventory.

We also found a high level of mechanical breakdowns, which drove missed production schedules and increased waste. For example, periodic equipment failures in the grinding room were causing an additional 1% to 1.5% yield losses.

Beyond system and process failures, we identified a lack of solid frontline leadership behaviors. There were no set performance expectations, and as a result, no expectations were enforced by leadership. This problem existed both between Managers and Supervisors and between Supervisors and their direct reports.

There was a high rate of employee turnover and a second shift staffed with 80% temporary employees. This ever-changing workforce presented massive challenges and increased the importance of having a solid leadership team communicating expectations and following up on executing those expectations.

Managers expressed a sentiment of being overwhelmed with the frequent changes to resource availability (human and equipment) and the need to quickly adjust the production and shipping schedules to meet customer delivery expectations. This continuous daily firefighting and ad-hoc approach to meeting customer demand strained the workforce and pushed it to a breaking point.

Plan

To Address Yield Loss:

- Our team installed Statistical Process Control charts on the eight production lines. These charts provide the control limits for acceptable patty and package weights. The Operators used the data in these forms adjusting equipment settings and reducing the number of overweight patties, thus reducing give away.

- As a temporary remedy, we placed reclamation tubs at the identified loss points to capture the excess meat spilling on the floor. Meat in these reclamation tubs was reintroduced to the process and helped reduce yield loss.

- We then replaced these reclamation tubs as we installed permanent mechanical fixes for the loss points. The fixes required working with outside contractors, OEMs, and a third-party maintenance team to fabricate and install guides and improve conveyance.

- We implemented a daily review of waste meat to understand the sources and identify measures to prevent the waste in the future.

- Our team conducted a study on the effectiveness of bone separator equipment to justify the purchase of an improved system that significantly reduced the amount of daily bone separator waste.

- We implemented a review of carryover meat in daily production meetings to ensure prompt reintroduction into the process.

- Our team trained Plant Management to conduct a daily review of production and yield reporting to address yield losses and to understand and rectify any anomalies in reporting.

To Address Frontline Leadership Challenges

- We worked closely with Supervisors and Managers to define their standard work routines and required performance outcomes. We then conducted periodic audits and coached frontline leaders on adherence to the newly established standards.

- Our team defined the cadence and the purpose of plant planning and performance reporting meetings. We coached meeting owners and participants on effective meeting behaviors and keeping action logs.

- We coached the management team on honoring their commitments by on-time completion of actions and following up on standard work routines.

- The POWERS team conducted Gemba walks (shop floor tours) with the management team to identify opportunities for improvement and define action plans.

- We implemented shift huddles to increase managerial communication and follow up on critical performance expectations with the frontline employees.

Results

Over the course of this project, the POWERS team helped the client achieve a 1% yield improvement, valued at close to $1 Million annualized. The planning and performance review meetings we implemented as part of the new Management Operating System (MOS) facilitated an additional 16% increase in productivity.