This meat packing industry leader faced market demand that strained long-standing operational systems, processes, and behaviors that left them unable to satisfy customers. Our team helped enhance scheduling, capacity, frontline leadership skills, and more. The results? Meaty productivity gains and $5.8 million in annual savings.

Project Overview

Performance Results

Background

Our client has deep roots and well-established brands in the meat processing and packing industry. They are renowned for their high-quality food products that combine four key components; top-quality meat, an expert blend of spices, natural wood smoking, and people who care about delivering quality food.

This time-tested recipe for success and established company traditions have helped them create delicious products and a thriving organization actively involved in its community. Like many companies in the food industry however, demand is skyrocketing yet unpredictable, placing strains on, and uncovering pre-existing operational weaknesses.

Situation

This stalwart company, behind some of the most beloved brands in their market space, found itself facing a need for increased throughput to satisfy customer orders and gain market share.

Management struggled to scale with paradigms that had worked for years, relying on systems, processes, and behaviors as ‘they used to do.’ The company also faced a generational management transition, as managers and frontline leaders who had been there for 20-plus years were getting ready to retire and take their years of experience with them.

With the holiday season quickly approaching, production needed to satisfy the most customers and increase yield, which had been in a steady decline for 75 weeks. As a result, lost Time was nearly equal to production time.

Additionally, no One Point lessons learned existed at the execution level. Instead, a ‘whatever it takes to get it out the door’ fire-fighting culture existed across the organization, from the top floor to the shop floor.

Top-Shelf Meat Packing Company Sees Meaty Gains in Productivity and a Healthy $5.8 Million Added to the Bottom Line

This industry leader in the meat processing and packing industry faced market demand that strained long-standing operational systems, processes, and behaviors that left them unable to satisfy customers. Our team helped enhance scheduling, capacity, frontline leadership skills, and more. The results? Meaty productivity gains and $5.8 million in annual savings.

Background

Our client has deep roots and well-established brands in the meat processing and packing industry. They are renowned for their high-quality food products that combine four key components; top-quality meat, an expert blend of spices, natural wood smoking, and people who care about delivering quality food.

This time-tested recipe for success and established company traditions have helped them create delicious products and a thriving organization actively involved in its community. Like many companies in the food industry however, demand is skyrocketing yet unpredictable, placing strains on, and uncovering pre-existing operational weaknesses.

Situation

This stalwart company, behind some of the most beloved brands in their market space, found itself facing a need for increased throughput to satisfy customer orders and gain market share.

Management struggled to scale with paradigms that had worked for years, relying on systems, processes, and behaviors as ‘they used to do.’ The company also faced a generational management transition, as managers and frontline leaders who had been there for 20-plus years were getting ready to retire and take their years of experience with them.

With the holiday season quickly approaching, production needed to satisfy the most customers and increase yield, which had been in a steady decline for 75 weeks. As a result, lost Time was nearly equal to production time.

Additionally, no One Point lessons learned existed at the execution level. Instead, a ‘whatever it takes to get it out the door’ fire-fighting culture existed across the organization, from the top floor to the shop floor.

Analysis

Our intensive analysis uncovered that the client was unable to reliably plan or forecast resource requirements due to inaccuracies and a lack of trust in their new ERP system. This was supported by observations we conducted on staffing levels and line balancing.

Without an established production schedule, the client was operating off constantly shifting “hot lists.” The squeakiest wheel, whether sales or a significant customer, gets the grease. This drove the client to be in a constant state of production firefighting and performing more frequent than optimal changeovers.

It was clear our client was fundamentally lacking a unified production schedule to reconcile how production resources would be distributed to meet these individual needs.

In addition, there were no operational KPIs or reports to indicate plant performance, resulting in little understanding of how well any given production line was performing. This lack of performance feedback was compounded by a culture where evaluation of past performance was never done at the process or line level.

Solution

We worked with production supervisors to construct line balance and SMED observations to ensure unique SKUs were set with reasonable expectations.

SKU Rationalization resulted in the purging of 90 low volume, low margin items from their offering, freeing up equipment to make higher volume, higher-margin products.

Working with the planning department, we developed a capacity model for the operation, enabling both short-term scheduling of lines and longer-term planning/forecasting of resource needs for the company.

Through training, development, and on the floor support of frontline leadership, we improved short interval scheduling, follow-up, and barrier identification at the supervisory level. This new level of support allowed frontline leadership to identify barriers better and to take action to address any variances.

Working with the production team, we developed lost time capture to the root cause and created actions to improve output and more closely perform to their capacity.

Unprecedented absenteeism during the Omicron CoV-19 surge led to the inability to staff lines and supervisors to become operators (nearly 25% absenteeism). However, we worked with the supervisors to perform line balances and staff lines with minimum staffing. This critical adjustment allowed production to remain functional, hit lbs./labor hour targets, and satisfy 92% On Time in Full (OTIF) of customer orders during the busiest season, avoiding meat allocation scenarios of the past (ration product to customers).

Results

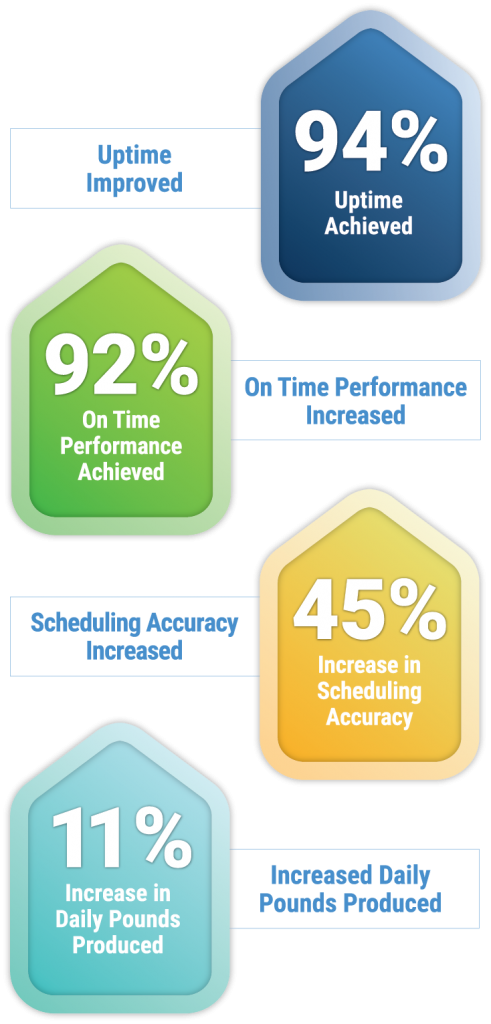

- Time studies and feedback loops between production management and support areas led to a 45% increase in scheduling accuracy (reduction of variance in pounds scheduled to pounds produced).

- Schedule execution and focus on Customers Due Dates have led to less expedites and an increase in on-time performance from 83% to 92%.

- 94% uptime was reached by improving focus on start-ups, maintenance rebuilds of problem equipment and lost time Root Cause Analyses.

- With a cleaner picture of the schedule, more organized staffing, and employee buy-in, production saw an 11% increase in daily pounds produced.

- Overall ham yield increased from 99% to 104%, for 8-weeks running (3,000,000 additional pounds, annually), and has continued post our initial engagement. The establishment of a Ham Yield Performance Improvement Team (PIT) was instrumental in cross-functional solutions being driven and implemented, creating sustainable solutions.

- Project reached break-even in week 16 and continues to add profit to the bottom line. $5.8M annualized at week 27 of the 28-week engagement.

- 2-months post engagement, MOS audit review scores continue to increase ownership level.

- 22% reduction in Product Giveaways (overweight to spec).

- 50% reduction in operational downtime, 18% to 9%.