Project Overview

Performance Results

Situation

In the dynamic world of food manufacturing, operational excellence is the key to staying competitive and ensuring high-quality production. In this case study, we explore the transformative journey of an anonymous food manufacturing company that embarked on a remarkable operational shift. With a vision to revolutionize its operations, the company partnered with POWERS to implement a Management Operating System based on Line Centric Teams (LCT).

The company’s traditional organizational structure featured separate leads for different shifts, reporting to shift supervisors and operations managers. Recognizing the

need for a significant operational shift, the company sought the expertise of POWERS to implement a Management Operating System centered around Line

Centric Teams (LCT).

Each LCT would comprise an operational line lead, a maintenance lead, and a process lead, responsible for overseeing one or more production lines. This marked a profound departure from their conventional structure, promising numerous benefits for the company and POWERS delivered

Analysis

POWERS began by conducting a thorough assessment of

the company’s current operations, identifying pain points

and areas for improvement. This involved observing

production lines, speaking with employees at all levels,

and analyzing data. From this assessment, POWERS

developed a tailored strategy for implementing the LCT

management operating system.

Before the transformation, the company faced several operational challenges. They lacked the ability to monitor floor performance effectively, with no hourly tracking of throughput relative to capacity. Short-interval follow-ups to address variances on the production lines were also absent.

Additionally, there was a lack of clear communication or publication of time-based expectations for capacity, task execution, and resource allocation. The lack of Key Performance Indicators (KPIs) and visual communications on the shop floor hindered team engagement and participation in Continuous Improvement (CI) initiatives and barrier identification and removal.

The assessment revealed several operational challenges that needed to be addressed:

- Ineffective Performance Monitoring: The company lacked the ability to monitor floor performance effectively, including hourly tracking of throughput relative to capacity.

- Lack of Short-Interval Follow-ups: Short-interval follow-ups to address variances on the production lines were absent, impacting response to operational issues.

- Unclear Communication: There was a lack of clear communication and publication of time-based expectations for capacity, task execution, and resource allocation.

- Absence of Key Performance Indicators (KPIs): The absence of KPIs and visual communications on the shop floor hindered team engagement and participation in Continuous Improvement (CI) initiatives.

The Plan

Recognizing the need for a substantial operational shift, POWERS was tasked with designing and implementing a comprehensive Management Operating System centered around the Line Centric Team (LCT) model. This plan encompassed various key elements to bring about a successful transformation. The detailed components of the plan included:

- Performance Metrics: Implementing a robust system for tracking and measuring performance across the production lines. This included defining key performance indicators (KPIs) to assess productivity, quality, and efficiency.

- Visual Management: Developing visual tools and communication methods to make performance data readily available on the shop floor. Visual aids such as performance dashboards and scorecards were introduced to enhance team engagement and facilitate

real-time decision-making. - Structured Tier Meetings: Instituting regular tier meetings within the Line Centric Teams to foster communication, share insights, and address issues proactively. These meetings aimed to ensure that all team members were aligned and informed about performance objectives.

- Short-Interval Follow-up Processes: Establishing processes for short-interval follow-ups to address variances and deviations promptly. This involved creating mechanisms for teams to respond quickly to operational challenges and maintain consistent performance.

- Centerline Establishment: Defining and implementing centerlines as benchmarks for performance. These centerlines represented the optimal operational state and allowed teams to understand the target performance levels and make real-time adjustments to maintain alignment with these targets.

- Defect Handling: Introducing structured defect handling processes to identify and address product defects or operational issues efficiently. This involved root cause analysis and corrective actions to prevent recurring defects.

- Root Cause Analysis Process: Implementing a systematic approach to root cause analysis to identify the underlying causes of operational issues. This process allowed teams to tackle the root causes of problems rather than just addressing symptoms.

The transformation initiative was structured as a 12-week sprint, with a deliberate focus on a single production line initially. This approach was designed to serve as a proving ground for the efficacy of the new Line Centric Team (LCT) model and Management Operating System.

The primary goal throughout this 12-week sprint was to achieve a throughput improvement of 5% over the base state. This targeted improvement would result in a 5% reduction in labor cost per pound and a 5% reduction in overhead cost per pound, demonstrating the immediate impact

and sustainability of the changes.

Results

The 12-week sprint produced remarkable results:

- Management Operating System Implementation: POWERS successfully introduced a management operating system on the designated production line, leveraging the newly formed Line Centric Team (LCT). This effort also included leadership development for the LCT.

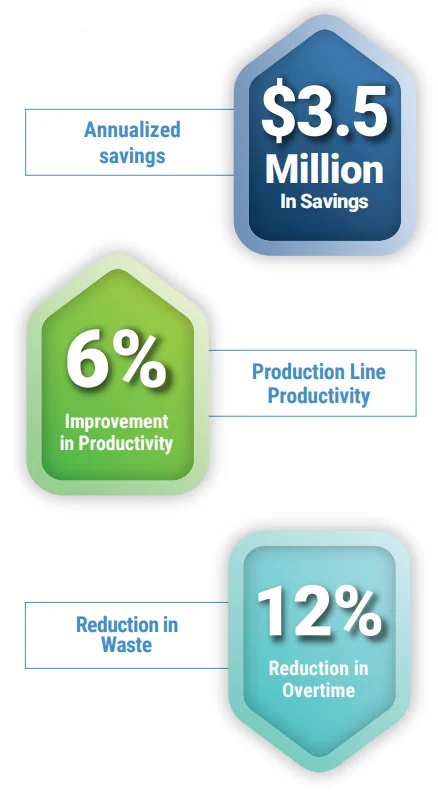

- Performance Improvement: Across the production line, there was an average increase in performance of 6% over the base state. This signified a substantial improvement in efficiency and output.

- Waste Reduction: The food manufacturing company managed to reduce waste on the production line by an average of 12% below the base state. This waste reduction translated to cost savings and enhanced overall operational efficiency.

- Cost Savings: The results of the 12-week sprint exceeded expectations, with cost savings reaching $344,000, far surpassing the initial target of $98,000. These savings amounted to an annualized figure of $3.46 million. This demonstrated not only the immediate impact but also the long-term sustainability of the implemented changes.

- Expansion of the Line-Centric Team Model: The success of the initial 12-week sprint was so evident that Dessert Holdings decided to extend the program. They added a second-centric team and began implementing the designed management operating system on three additional production lines. This expansion showcased the scalability and replicability of the new model.

The transformation journey from a traditional organizational structure to the Line Centric Team (LCT) model led by POWERS was a resounding success for this food manufacturing company. Through improved performance, reduced waste, and significant cost savings, the company demonstrated its commitment to operational excellence and continuous improvement. This case

study serves as a testament to the power of reimagining organizational structures and embracing innovative management systems to drive success in the competitive world of food manufacturing.