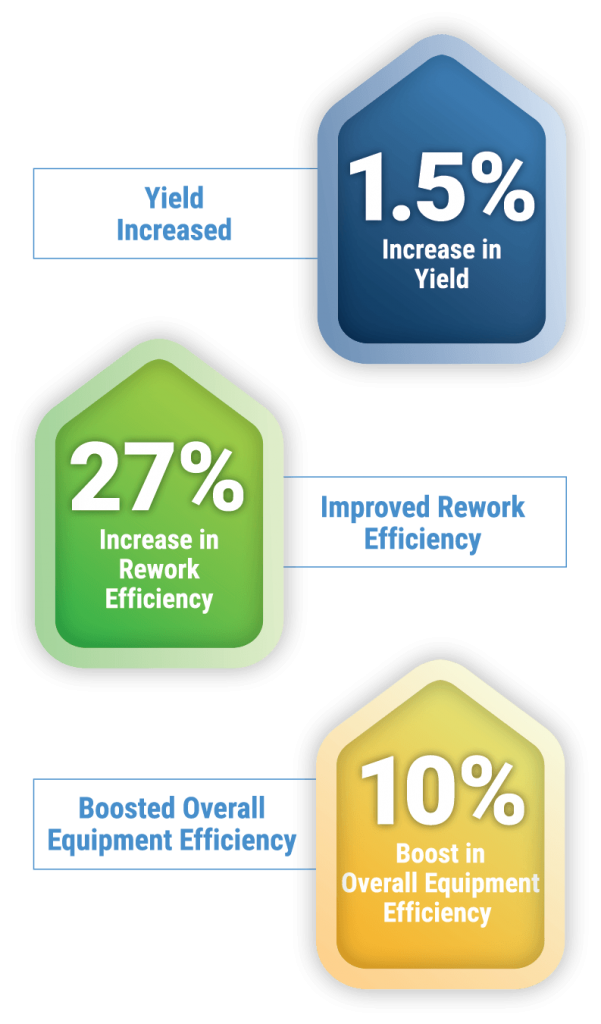

Our client, a world-class producer of pre-cooked barbeque products, needed to reduce costs and fatten margins while increasing throughput and yield. Its disconnected, ever-changing schedules created poor production flow, resource shortages, and overbuilding. Overstaffing with temporary workers and overreliance on inaccurate forecasts drove up costs. The POWERS team examined and addressed every item affecting yield, equipped managers with training and tools, and aligned resources with production. The results? A satisfying $2.2 million in projected annual savings and a hearty 1.5 percent gain in yield.

Project Overview

Performance Results

Background

Our client produces and distributes pre-cooked, sauced, and ready-to-heat barbeque ribs, pork, and chickens. The company’s 200-plus products generate annual revenues

of $150 million using approximately 350 full-time and temporary employees.

However, It needed to increase yield, improve flow and reduce costs throughout the production process to meet margins while optimizing a temporary labor pool.

After numerous successful projects at his previous company, the COO engaged POWERS to realize savings opportunities with sustainable results. We primarily focused on four functional areas: the Cutting Room, Seasoning and Ovens, Ready-to-Eat (RTE), and Planning and Scheduling.

Situation

Our business analysis revealed that managers and supervisors did not have the tools or training to manage their areas profitably or make sound business decisions.

Unbalanced production lines led to overcrewing, made worse by regularly bringing in far more temps than needed for the day’s production. Yield management was only tracked in one area instead of across the entire process. Managers didn’t pay attention to temperatures, waste or giveaway, or recognize each department’s impact on yield.

What’s more, there was a lack of collaboration between Sales, Supply Chain Management, and Operations. Sales had no accountability for inventory but pushed for higher levels to ensure orders could be filled. These inaccurate forecasts led to excess inventory.

Background

Our client produces and distributes pre-cooked, sauced, and ready-to-heat barbeque ribs, pork, and chickens. The company’s 200-plus products generate annual revenuesof $150 million using approximately 350 full-time and temporary employees.

However, It needed to increase yield, improve flow and reduce costs throughout the production process to meet margins while optimizing a temporary labor pool.

After numerous successful projects at his previous company, the COO engaged POWERS to realize savings opportunities with sustainable results. We primarily focused on four functional areas: the Cutting Room, Seasoning and Ovens, Ready-to-Eat (RTE), and Planning and Scheduling.

Situation

Our business analysis revealed that managers and supervisors did not have the tools or training to manage their areas profitably or make sound business decisions.

Unbalanced production lines led to overcrewing, made worse by regularly bringing in far more temps than needed for the day’s production. Yield management was only tracked in one area instead of across the entire process. Managers didn’t pay attention to temperatures, waste or giveaway, or recognize each department’s impact on yield.

What’s more, there was a lack of collaboration between Sales, Supply Chain Management, and Operations. Sales had no accountability for inventory but pushed for higher levels to ensure orders could be filled. These inaccurate forecasts led to excess inventory.

Our Approach

Our team examined and addressed every item that impacted yield in all four of our client’s business areas.

We connected cause and effect within management, systems and processes, people and behavior, equipment, and materials to achieve significant improvement in yield, frontline supervision, and production-based resource management.

We evaluated and revised the existing standards for each product, then used them to create a crewing tool that specifies the correct number of people needed on the line by product code for more efficient use of temporary labor.

We worked on the floor with area managers and supervisors to improve yields and margins while empowering them to manage more effectively.

The Results

• Upgraded the Management Operating Systems

• Streamlined and synchronized production schedules between departments

• Re-evaluated resource and production standards for all 200-plus products

• Created a crewing tool that matches resources needed to the day’s production requirements

• Enforced cutoffs for changes to the schedule, eliminating resource outages and overbuilding

• Decreased backlogs and indirect labor costs in cutting room

• Implemented yield tracking by stage to measure gain against standards

• Reduced overbuilding and emergency requests with better planning and scheduling

• Instituted management in short intervals to ensure daily production levels are met

Trimmed Cutting Room Excesses

Out-of-balance lines in the cutting room created a backlog at the trimming stations, resulting in an uneven flow to packers. In addition, employees were not cross-trained to backfill other departments during low-production periods, leaving cutting room staff idle while other departments were busy. Because production schedules only existed on a daily basis, with no shorter-interval controls, there was often excess work in progress.

Our team eliminated bottlenecks by aligning the number of temps ordered to the day’s production requirements. New tools that equip supervisors to manage production over short intervals ensure that daily levels are met and not exceeded.

Adjusted Seasoning and Ovens

Multiple issues hampered scheduling and reduced yields. Some materials were not available when needed – or the day’s schedule was overproduced. Meat was coming into seasoning too warm, and brine temperatures were higher than optimal. In addition, meat was seasoned and cooked on screens stacked two and three deep, reducing product weight. And although the plant had vacuum-tumbling equipment, it was not being used.

Our consultants worked with managers to set target temperatures throughout seasoning and cooking. As a result, product stacking has been minimized and vacuum tumbling optimized to increase yield. We also implemented yield tracking by stage to measure the gain against the new standard for each product.

Retooled Ready-to-Eat

In this area, where product is packaged, the schedule frequently changed during the day, limiting managers’ ability to plan resources. High amounts of product had to be reworked because operators were not properly trained, and there was no process to minimize rework.

A Fresh Focus on Flow Through Planning and Scheduling

Planning and scheduling issues permeated the production process. Seasoning/Ovens cooked too much meat for RTE to keep pace, so they stored it in the frozen warehouse.

However, the thawing schedule for frozen meat didn’t match the cutting schedule, so it wasn’t ready. RTE received frequent rush orders and requests from Sales that caused changes throughout the day. Schedules were siloed by department and disconnected, disrupting the flow through the plant. Large amounts of meat awaited packing because workloads weren’t planned adequately across departments.

Prebuilding took place early in the year to save time during the busy grilling season, but often, too much product was built.

We developed a tool that has streamlined and linked all schedules, improving the flow across the production process. Now, all orders or changes to the schedule must be submitted the day before, eliminating resource shortages and overages in production areas.

Because resources were not aligned to production, 20 to 30 people brought in might have little to do. Although managers tracked Overall Equipment Efficiency (OEE), they didn’t act on the information. And, with no link to inventory, costlier packaging film might be substitute if the specified film was discovered out of stock.

Line staffing is now balanced, based on each product’s new standards. Products needed for production are staged the day before to improve startup scores. We engaged operators in improvement by reporting their hourly production percentages. Managing in short intervals maintains daily production levels. We also taught managers and supervisors how to use OEE information to pinpoint improvements needed to meet their daily OEE targets.

Changes Yield Robust Results

Partnering with this client is projected to reap benefits of $2.2 million at normal production levels for their business, primarily through savings in temporary labor. The crewing tool has decreased backlogs and indirect labor hours, while yield has improved by 1.5 percent. We improved rework efficiency by 27 percent in RTE and Overall Equipment Efficiency (OEE) by 10 percent. Managers now have the tools, training, and information to manage the business and sustain these operational performance improvements.

Sustainability Measures

• Provided daily on-the-floor coaching with supervisors

• Helped them set standards for each area

• Taught them to read their reports and use the information to make business decisions

• Created roles and responsibilities to reduce overlap of tasks

• Documented procedures for all of the tools

• Involved HR to ensure staffing with qualified individuals who could use the tools