Real-Time Production Insights to Drive Productivity and Profitability at Your Fingertips.

Introducing Powers DPS, the Digital Production System that Delivers Accurate, Real-Time Actionable Insights for Better Planning, Better Decisions, and Better Outcomes. Learn More.

CURRENT STATE

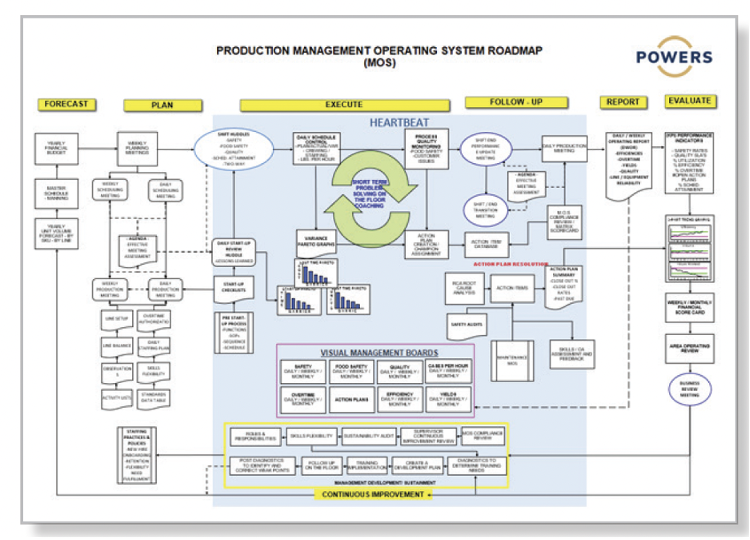

The Manufacturing Operating System: The Traditional Key to Operational Success

For decades, many of the world’s leading global manufacturing organizations have relied on production and management operating systems deeply rooted in lean principles, continuous improvement, and performance standards to achieve a sustainable market advantage. These systems are designed to deliver significant cost savings, enhance efficiency, and uncover new opportunities for improvement at both the site and functional levels.

FUTURE STATE

Digital Operating Systems Represent the Future But Have Their Challenges

Organizations that have made or are planning to make optimization and continuous improvement the foundation of their operations must leverage the next generation of corporate production systems, known as ‘digital operating systems.’

Modern enterprises must make near real-time decisions based on accurate data in today’s fast-paced business environment. Leaders require precise and relevant insights into live operations to stay competitive.

Traditional lean-based systems, such as the Toyota Production System (TPS), world-class manufacturing (WCM), and total quality management (TQM), are increasingly limited in their ability to deliver the necessary speed and agility. While effective in their time, these systems are now struggling to keep up with the pace of change and the volume of data that digital operating systems can handle.

Digital operating systems represent a new approach that integrates lean and continuous improvement principles with smart manufacturing technologies. As organizations stand at the crossroads of lean tenets and digital transformation, harnessing these new technologies to respond more flexibly to shifting market demands is critical.

Modernizing Your MOS: Balancing Proven Methods With a Powerful Digital Tool Box

1. THE OBJECTIVE

Unlocking Superior Performance

The advent of digital operating systems will not alter corporate production systems’ fundamental purpose but will revolutionize how they are constructed and managed.

These systems will integrate cutting-edge technologies and digital capabilities with lean and continuous improvement principles to enhance overall agility and performance throughout the entire value chain.

2. The Challenge

Transforming Data to Insights to Actions

Although these evolving technologies will increasingly handle transactional tasks, the real challenge lies in their ability to provide leadership and management with actionable insight to guide the company’s strategic direction and drive sustainable business improvement.

Just as cars are becoming more advanced every day, they still depend on the driver. A car’s computer can alert you when the tire pressure is low but can’t diagnose uneven tire wear caused by a faulty shock absorber.

3. THE ADVANTAGE

Introducing Powers DPS

That’s why we’ve developed Powers DPS (Digital Production System). Our advantage lies in our holistic approach that emphasizes both technology and leadership behavior across your operation.

Unlike solutions focusing solely on connectivity and visibility, Powers DPS software integrates nearly two decades of hands-on productivity consulting experience. Our expertise in process improvement, system development, implementation, and behavior change has consistently transformed our partners’ businesses.

This real-world knowledge is now combined with an easy-to-use technology solution designed to enhance management capabilities and drive sustainable and scalable business performance, providing you with practical benefits you can rely on.

4. THE RESULT

Boosted Productivity and Profitability

With Powers DPS, you’ll have a more profitable business driven by a fully implemented and sustainable Digital Production System.

But beyond that, you’ll have an engaged workforce with true ownership of their areas and the knowledge to help their team win every hour, shift, day, and week.

![]()

Powers DPS Unlocks Sustainable and Scalable Performance Improvement

Powers DPS is a comprehensive, next-generation manufacturing operating system that offers practical benefits for your team. Its real-time data, advanced analytics, and AI-powered insights empower you to make informed decisions that drive performance improvement.

Built by operations professionals with decades of hands-on experience, Powers DPS combines the best of lean manufacturing principles with cutting-edge digital technology to streamline processes, improve productivity, and drive sustainable performance increases throughout your value chain.

FEATURES

Gain a comprehensive view of your site's production performance with our dynamic dashboard, featuring essential Key Performance Indicators (KPIs) and metrics:

- Startup Scores - Measure the effectiveness of production line startups.

- Production Output - Track your total units produced.

- Downtime Percentage - Monitor downtime to identify areas for improvement.

- Units per Labor Hour - Optimize productivity by comparing units produced against labor hours.

- Total Capacity Utilization - Break down utilization into Attainment, Identified Lost Time, Reject/Waste, and Unidentified Lost Time.

- Startup Scores by Line - Evaluate line-specific startup performance.

- Capacity Utilization by Line - View utilization data across different production lines.

- Units / Labor Hour: Analyze productivity metrics.

- Downtime % and Minutes: Visualize downtime trends and their impact.

- Production Run Minutes: Monitor overall production efficiency.

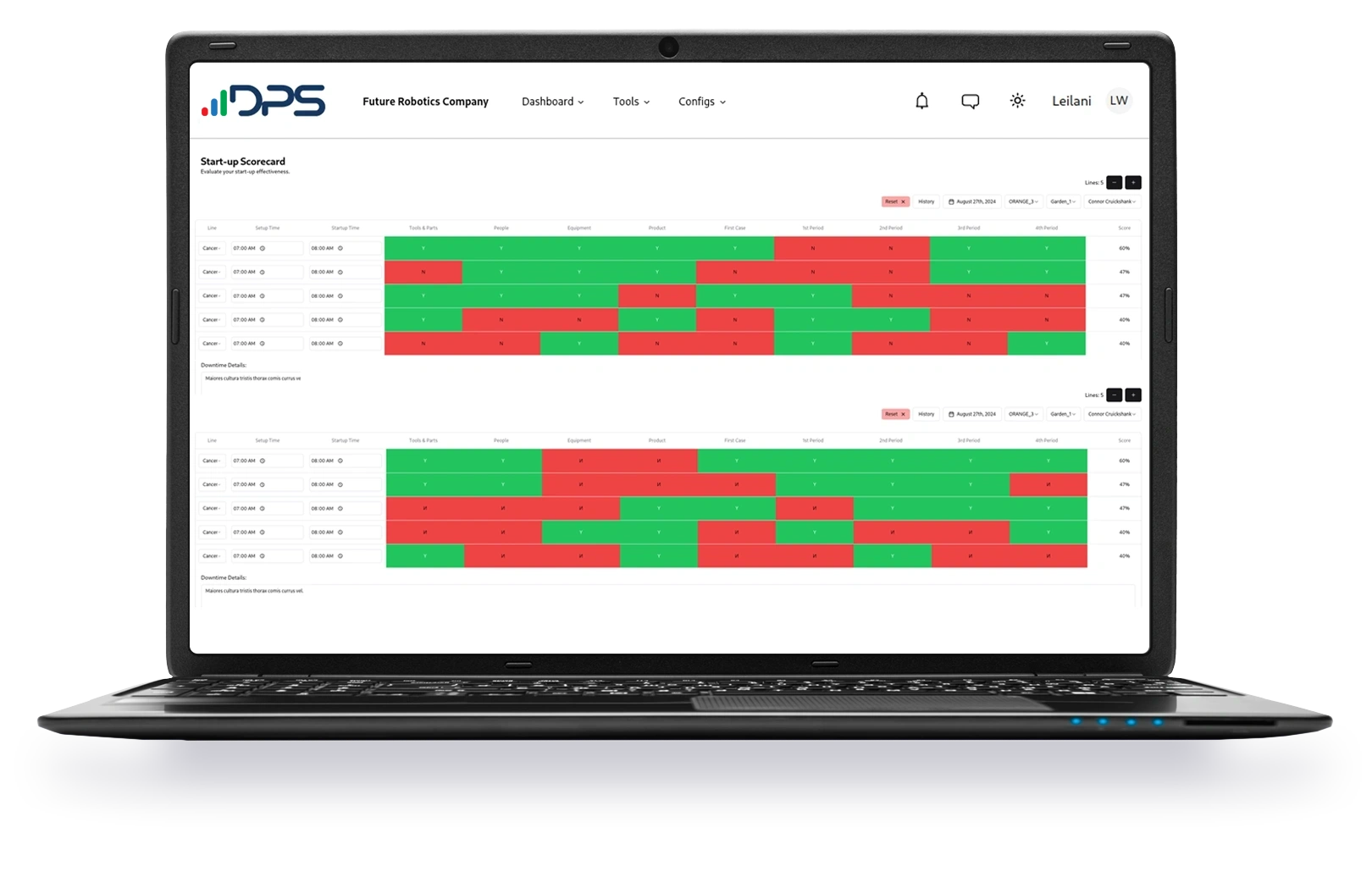

Evaluate startup effectiveness with detailed scorecards.

- Startup Score %: Use preset criteria Powers recommends or customize your own to measure startup performance.

- Track long-term trends to improve startup management.

- Supervisors can log performance metrics across multiple lines, including Setup Time, Startup Time, Line Readiness, and First-Hour Uptime.

- Document startup performance issues in the comments section.

Track, measure, and report performance enhancements for repeatability, fostering a culture of continuous improvement and scalable advancements.

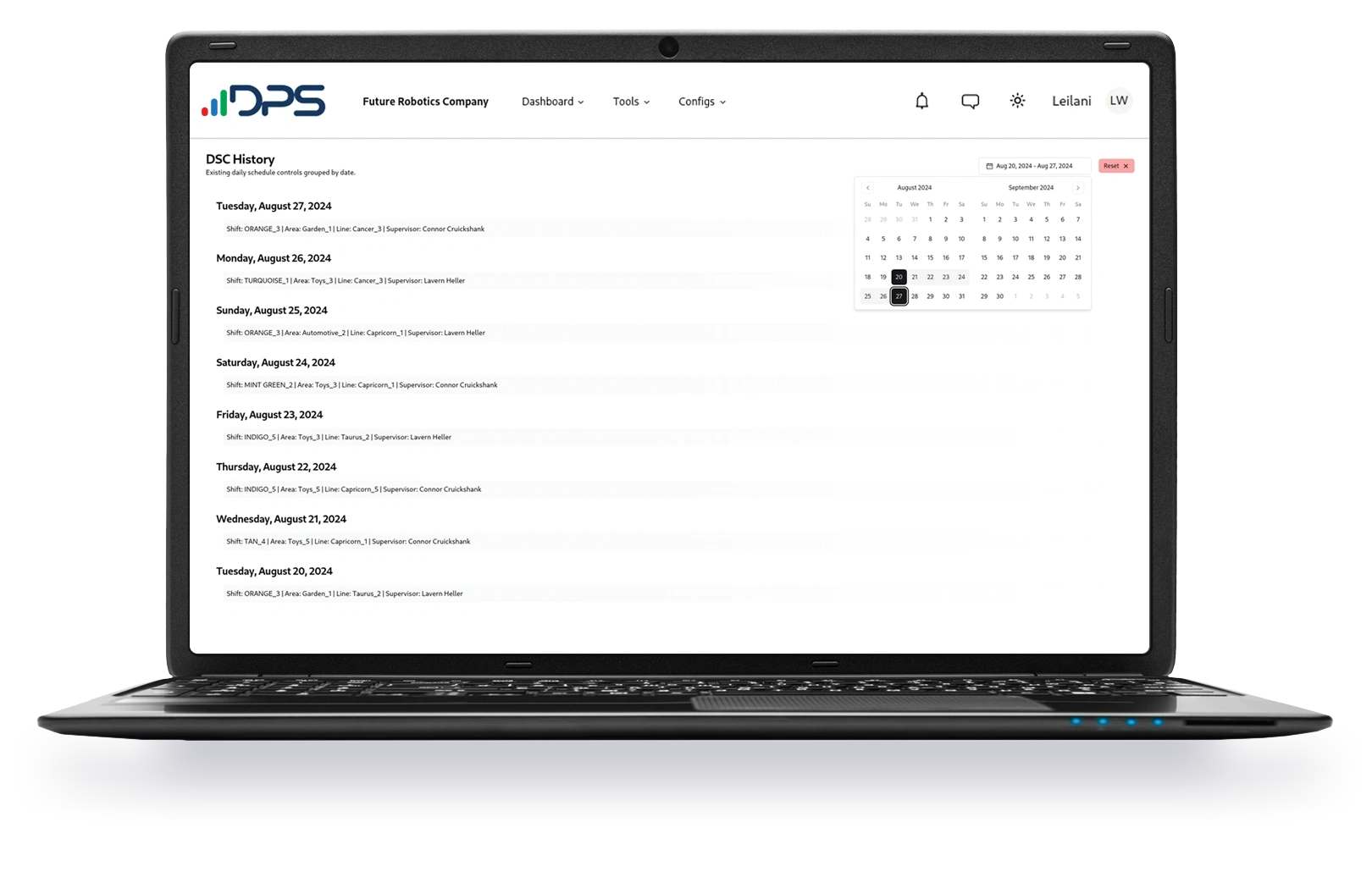

Quickly create and manage downtime events.

- Use the Downtime Tracker or integrate with the DSC tool to log events.

- Visualize downtime with Pareto (80/20) charts to pinpoint top downtime causes.

- Multiple chart types: Sum (minutes) and Occurrences (count).

- Group and filter downtime data by Date, Shift, Equipment Code, Product Code, Line, Area, Reason Code, and more.

- Drill down into downtime causes with instant chart updates and advanced filtering.

![]()

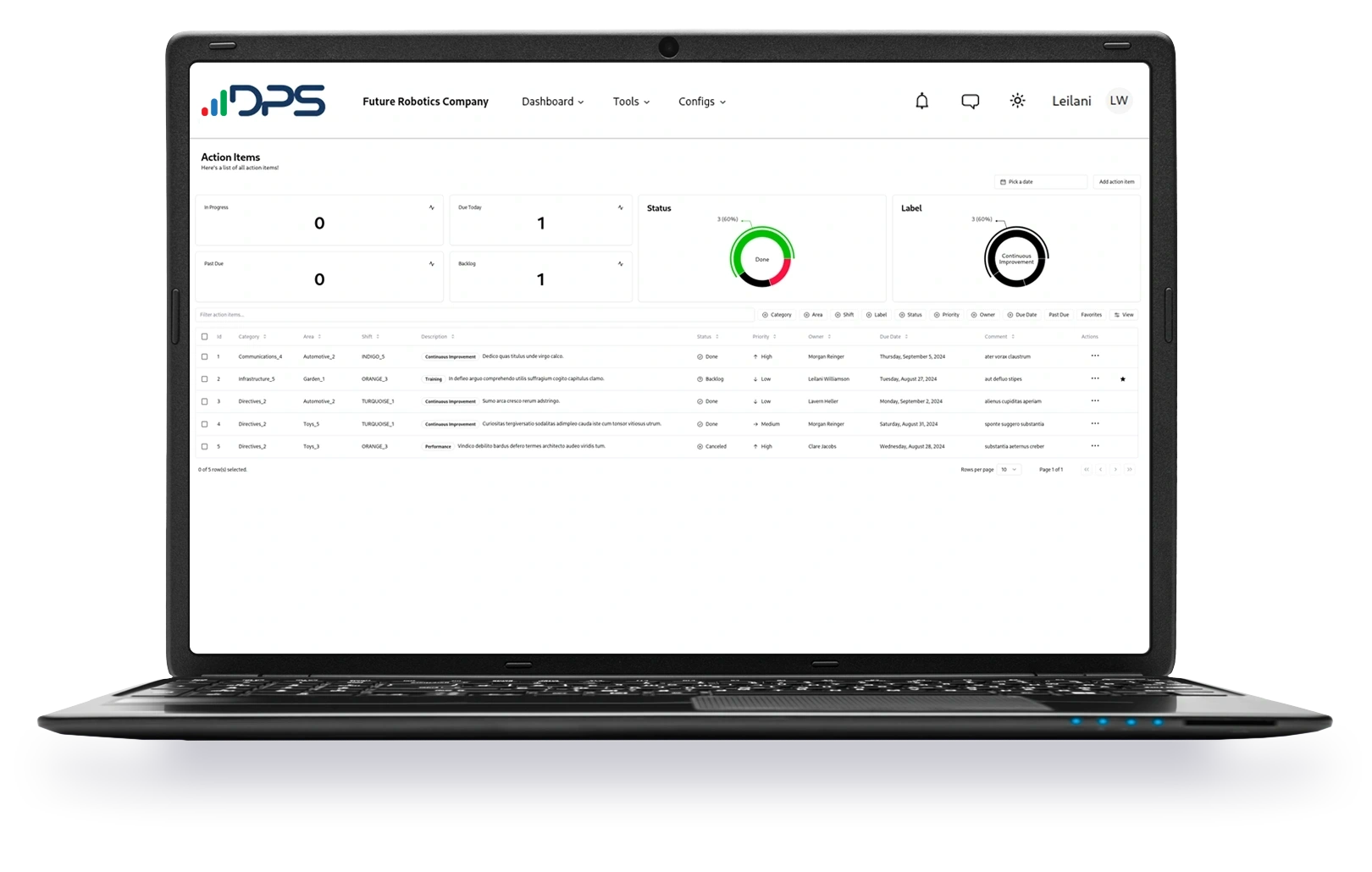

Track corrective actions to drive continuous improvement.

- Action Item Dashboard: View in progress, due today, past due, and backlog action items.

- Visual Overviews: Pie charts show the status and labels of action items.

- Advanced filtering and fuzzy search to find specific action items.

- Automated past-due highlights and completion tracking.

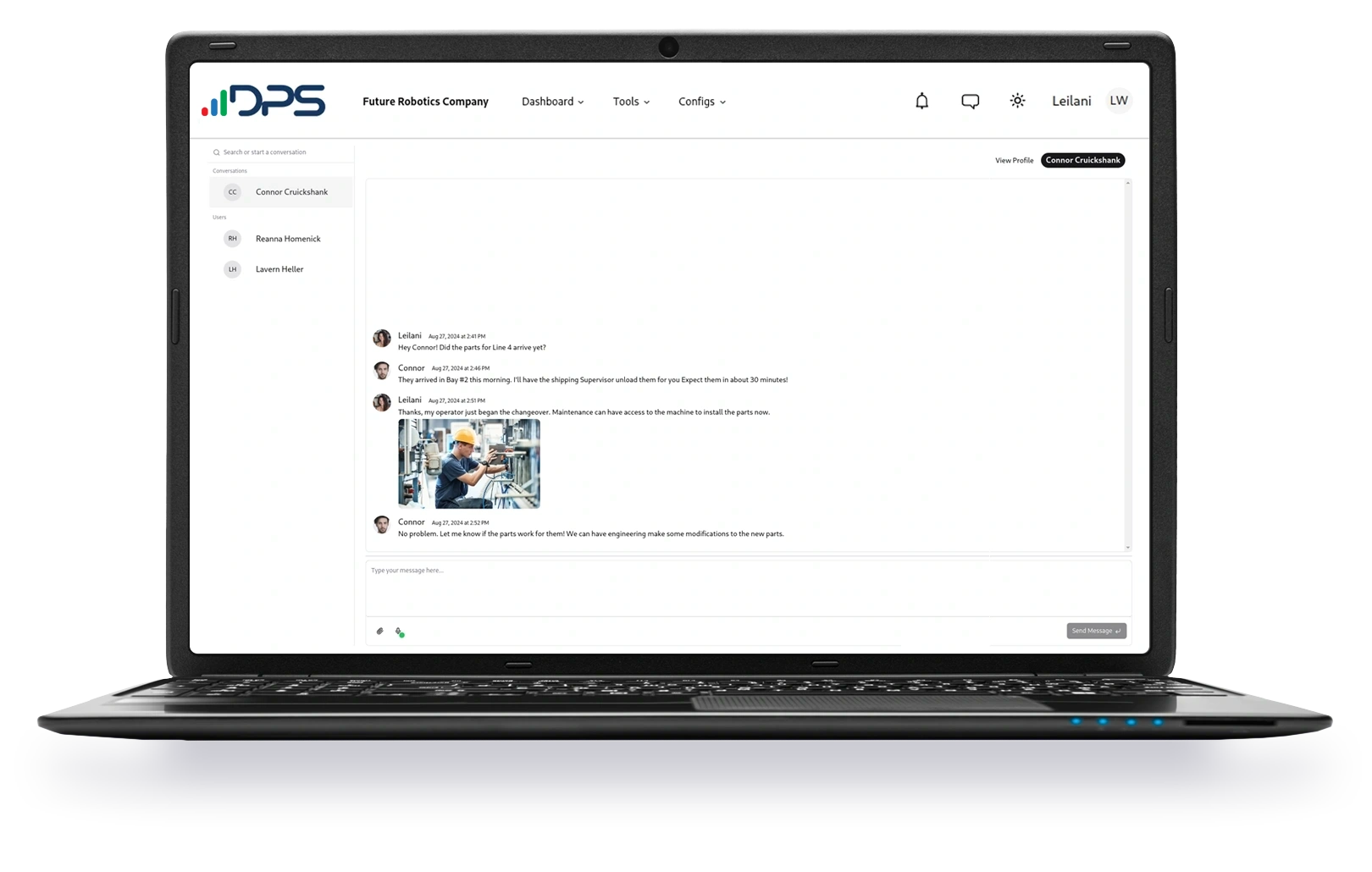

Stay connected with direct messaging.

- One-on-one messaging with media and file attachments, including images, videos, documents, PDFs, and audio files.

- Audio transcription for voice-to-text messaging.

- Real-time notifications and unread message counts.

- Fast, cached loading and deduplication of shared media.

Explore the full suite of DPS features and benefits on our Digital Production System website.

Experience the Powers DPS Advantage

Experience the transformative power of Powers DPS and unlock the full potential of your manufacturing operations. Our comprehensive solution goes beyond traditional software, offering a proven system built on real-world expertise, intuitive design, real-time connectivity, and data-driven insights. Discover how Powers DPS can empower your team and drive sustainable growth.

KEY BENEFITS

Proven Manufacturing Operating System Toolbox

Powers DPS is not just a theoretical solution; it’s a practical, proven system born from real-world experience. Our team has implemented complete manufacturing operating and production systems (MOS) for some of the world’s most respected manufacturing companies, ensuring their operations run smoothly, efficiently, and profitably.

With this hands-on experience and deep industry knowledge, we’ve developed tools that truly work—helping companies increase productivity and optimize their plants to world-class levels.

These tools are not abstract concepts but have been refined and enhanced over years of collaboration with real clients on real manufacturing floors, driving tangible operational improvements.

Simplicity for an Unmatched User Experience

Powers DPS is the first manufacturing software built by operations teams for operations teams—designed by professionals who have worked on manufacturing floors. It’s crafted to make the lives of manufacturing teams easier, helping them achieve more and ‘win’ every shift by delivering only the essential tools, free from unnecessary clutter.

The user-friendly design ensures rapid adoption across your organization, with features that are easy to use, reducing the need for complex training and eliminating long learning curves. Powers DPS prioritizes simplicity, ensuring that everyone—from the shop floor to the top floor—can use it effectively and efficiently.

Real-Time Digital Connection

Powers DPS represents the digital evolution of our manufacturing expertise, empowering everyone in your organization to make informed decisions in a rapidly changing landscape. With real-time communication tools and visibility at all levels, DPS fosters enhanced collaboration and engagement across departments or facilities, driving continuous improvement throughout your entire operation.

This connectivity translates into faster insights, better problem-solving, and greater productivity, ensuring that your organization remains agile and responsive to change.

Data Integrity and Actionable Insights

In manufacturing, data is only valuable if it’s accurate and actionable. Too often, companies find themselves “data-rich but insight-poor” or struggling with unreliable information in a “garbage in, garbage out” data environment. Powers DPS is built on a commitment to delivering reliable, accurate data that fuels rapid and sustainable performance improvement.

With user-friendly data input and advanced sensor connectivity options, Powers DPS ensures up-to-the-minute accuracy, empowering your team to make decisions based on the most current information. This commitment to data integrity, backed by decades of experience, enables everyone in your organization to make informed, impactful decisions.

Empower Daily Huddles and Strategic Planning

Powers DPS provides real-time visibility into key performance indicators, facilitating effective daily huddles and strategic planning. With data-driven insights, your team can quickly identify bottlenecks, deviations, and opportunities.

Additionally, Powers DPS supports long-term planning by offering historical data and trend analysis, allowing you to anticipate challenges and capitalize on opportunities.

Scalable for Growth

As your business evolves, Powers DPS scales with you, providing you with the confidence that it can adapt to your changing needs. Whether expanding production lines or entering new markets, Powers DPS seamlessly integrates across departments and facilities, providing comprehensive visibility into the data that matters most.

Reduced Total Cost of Ownership (TCO)

Powers DPS consolidates your software needs, eliminating the need for multiple communication and productivity platforms. This efficient approach reduces initial and ongoing costs while streamlining your technology stack without compromising functionality or performance, resulting in significant savings.

AI-Powered Insights and Action Planning

With advanced AI algorithms, Powers DPS uncovers hidden patterns and trends within your data, automating analysis to identify optimization opportunities. It provides actionable recommendations for performance improvement, such as enhancing capacity utilization and minimizing unplanned downtime. This intelligent, practical use of AI saves time and directs resources to initiatives with the highest impact.

Better Insights. Better Planning. Better Decisions. Better Actions. Better Outcomes.

Lock In Sustainable and Scalable Performance Improvements with Powers DPS

The future of your manufacturing operations starts here. Let Powers DPS help you take the next step in productivity, efficiency, and growth. Contact us to see how we can customize a solution for your business needs.