This wholesale plant grower and distributor needed to prune its labor expenses and increase the performance of its workforce. So we worked from the ground up to establish productivity measures, set expectations, coach supervisory skills, and cultivate leadership. As a result, the company has reaped productivity improvements and bottom-line benefits from sustainable labor savings, a higher volume capacity, and a nearly 4-to-1 return on its consulting investment.

Project Overview

Performance Results

Situation Analysis

Our client is a South Carolina-based wholesale grower and distributor of perennial and ground- cover plants. It sells approximately 14 million plants annually to national retail garden centers, such as Lowe’s, Home Depot, Walmart, and other specialty growers and distributors.

The company’s farm operations require crews of workers to tend to plants throughout the year. However, the wholesale flower business is highly seasonal: The 10-week peak selling season (April 1 to mid-June) accounts for 53 percent of sales. During this time, workers with tractors and trailers are given a picklist with the numbers and types of plants needed each day. Plants are then taken to shipping, assembled by order, placed on carts, directed to the appropriate trucks, and dispatched for delivery.

Business was good, but the company needed to reduce its labor costs and boost productivity, particularly during the peak season. In the past, the client would merely hire more workers at the start of the season, but there was no way to establish the actual headcount required to handle any given volume of work. In addition, there were no established productivity measurements, so no one in the organization knew how they were performing.

And although there were forecasts and good historical information available, this data was never integrated into a Management Operating System (MOS) that was usable to a first-level farm supervisor.

The company sought to lower its costs per unit shipped and increase revenues without increasing labor costs. However, there was a lack of leadership and ability at the production level to define and improve processes.

Situation Analysis

Our client-partner is a South Carolina-based wholesale grower and distributor of perennial and ground- cover plants. It sells approximately 14 million plants annually to national retail garden centers, such as Lowe’s, Home Depot, Walmart, and other specialty growers and distributors.

The company’s farm operations require crews of workers to tend to plants throughout the year. However, the wholesale flower business is highly seasonal: The 10-week peak selling season (April 1 to mid-June) accounts for 53 percent of sales. During this time, workers with tractors and trailers are given a picklist with the numbers and types of plants needed each day. Plants are then taken to shipping, assembled by order, placed on carts, directed to the appropriate trucks, and dispatched for delivery.

Business was good, but the company needed to reduce its labor costs and boost productivity, particularly during the peak season. In the past, the client would merely hire more workers at the start of the season, but there was no way to establish the actual headcount required to handle any given volume of work. In addition, there were no established productivity measurements, so no one in the organization knew how they were performing.

And although there were forecasts and good historical information available, this data was never integrated into a Management Operating System (MOS) that was usable to a first-level farm supervisor.

The company sought to lower its costs per unit shipped and increase revenues without increasing labor costs. However, there was a lack of leadership and ability at the production level to define and improve processes.

Supervisors consisted of workers who had risen through the ranks without training in supervisory skills or the tools or information to be truly effective leaders. They did not know how to set expectations for their crews and hold them accountable for a particular finish time or the number of hours worked.

Our Approach

Because the client’s processes are relatively simple, the MOS did not need to be overly complicated. But to work,

it needed to be built from the bottom up. So we conferred with the people in the fields, potting lines, and propagation room to establish crew sizes and get “real-life” training on how to address lost time and core performance. Next, we implemented a process for looking ahead one to three weeks and at data from previous years to identify patterns.

Working together, we built ramp-up plans based on projected loading volumes, then helped supervisors determine how quickly to cut the loading workforce as the season wound down. In addition, we consulted with the growers and supervisors on the farm maintenance side to establish the number of tasks that could be done per hour, based on their observations and experience.

These collaborative efforts resulted in a method to plan a shift’s work, the ability to measure the efficiency of that work, and a way to “keep score.”

The Results

Supervisors learned how to define the work to be done in a quantifiable way and to establish the expected rate. They now know how long it takes a crew of a given size to accomplish specific tasks, so they can lay out the day’s work schedule up front and reasonably fit more work tasks into the day.

We showed them how to apply the concepts, then reinforced them as they practiced to ensure success, coaching their behavior as well as their technical management skills.

Based on the current annualized savings rate, our partner realized a 3.9-to-1 return on its consulting investment.

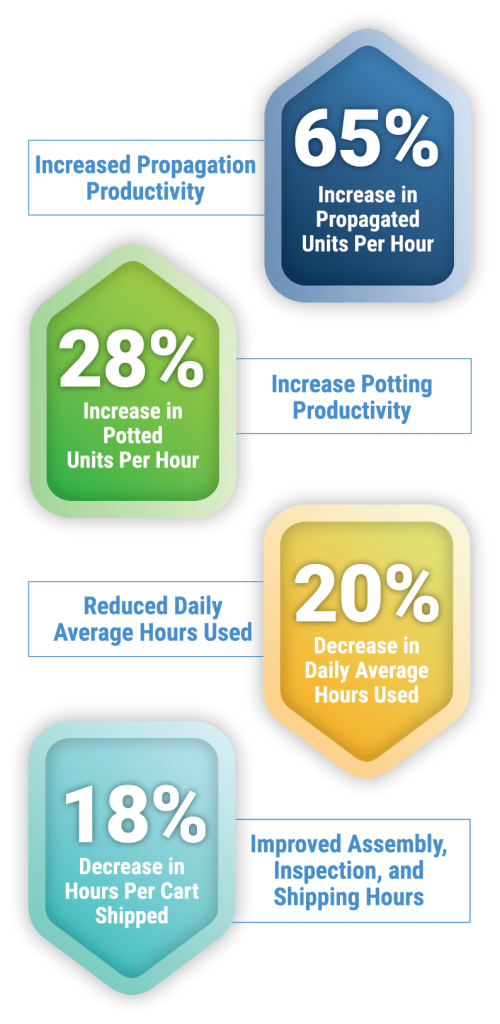

The company has achieved its dual goal of boosting productivity and reducing labor expenses. It increased the number of units propagated by 65 percent and the number of units potted by 28 percent per hour. It decreased the hours used per cart shipped by 18 percent.

And, during the highest-volume week, it reduced the workforce and the daily hours worked per employee by 11.5 percent. This resulted in a 23 percent improvement in carts per hour.

Additional benefits of our engagement included:

• Efficiently organized supplies and warehouse inventory controls

• Improved equipment reliability, with new processes to keep tractors fueled and batteries charged

• Analysis showing that land identified for acquisition could support the volumes needed to justify the lease/purchase

The POWERS approach of working side-by-side with frontline leaders in their specific area leaves the organization better trained and provides the power to sustain improvements. In addition to the financial gains, the client has experienced positive changes in its company culture.

Today, planning is visibly improved throughout the organization. Instead of simply working around problems, everyone is now willing to bring them up for discussion and work together to solve them. Just as important, people share their successes for improvement—taking pride in what they have “fixed lately.”