Project Overview

Performance Results

Situation

Our client, a leading home furnishings manufacturer with a flagship 400,000 sq. ft. facility, faced operational challenges that threatened its growth potential. Space limitations, rising costs across multiple locations, and inefficient processes leading to multiple product handling points hindered their ability to maximize output.

Senior leadership recognized the need to improve their team’s management skills. The team lacked experience confronting and solving problems, utilized no metrics to drive decision-making and report-outs, and had an ad hoc planning style. Additionally, they wanted to optimize their operation with established structures and processes before an upcoming ERP installation.

Analysis

Our analysis confirmed the leadership team’s challenges with basic management skills. Metrics were absent in most departments except for raw production counts. Process mapping, from Receiving through Production to Shipping, revealed a significant lack of essential planning, follow-up, and execution. Frustration was evident in the work environment, but a deeply ingrained culture resisted taking action. Everyone liked to talk about a problem, but they all wanted someone else to do something about it.

Plan

The POWERS team partnered with our client’s leadership team on a comprehensive strategy:

- Transition from decentralized production to streamlined cell manufacturing.

- Provide personalized coaching for the management team to develop their leadership skills.

- Conduct 10 workshops targeting key skills such as managing by the numbers, constructive confrontation/coaching/follow-up, and root cause analysis.

- Develop tools to strengthen the operational system, introduce metrics and reporting structures, and establish a planning routine.

- Conduct observations to determine line capabilities and support line balancing.

- Document every process and tool change to facilitate future reference and smooth ERP integration.

Results

Over the engagement, the POWERS team assisted our client in achieving their goals:

Operational Efficiency

- Recovered over 1/3 of the 400,000 sq. ft. facility.

- Eliminated over 2500 baskets, reducing inefficient product handling.

- Established 13 manufacturing cells (6 with daily operation), with capacity for expansion.

- Introduced the concepts of pieces/hour in production and earned hours for work completed in Receiving and Shipping.

- Integrated the Packing department into the cell structure, improving efficiency and staffing optimization.

Financial Impact

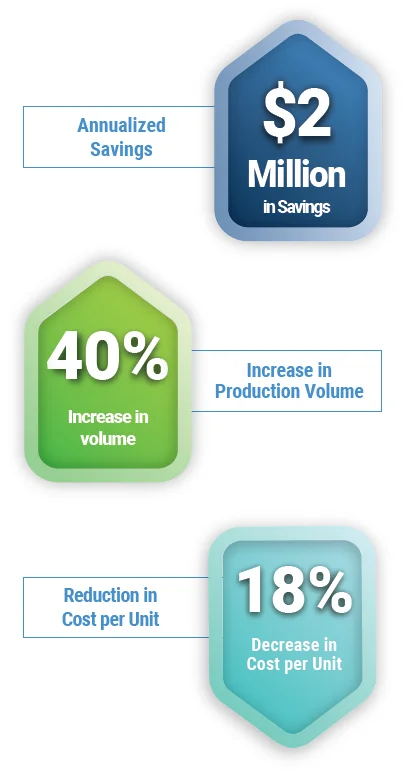

Company leadership, while analyzing and seeking to understand the full impact of the change, remarked that early 2024 saw an 18% improvement in cost per unit and a sustained 40% increase in volume from 2023. A senior VP noted that a task once requiring 36 Fillers now only took 24.

Additional Improvements

- Supported the reorganization of a sizeable product segment.

- Helped effectively absorb unplanned business from a client that threatened to disrupt the process.

- Reorganized the front end of the process (Ticketing) to improve piece counts and drive down over-production.

- Partnered with the leadership team to capitalize on the freed-up warehouse space, better locate and account for inventory, and establish a pre-labeling area for boxes.

Manufacturing Enhancements

We identified a base performance of 176.82 units/nozzle hour. Over the engagement, we increased performance to 263.78, a 49.2% improvement.

Financial Summary

- Target savings for the end of the engagement was 166% of the goal.

- Annualized savings were $2,121,562,96.

- Achieved positive cash flow 15 weeks ahead of plan.

Our client’s confidence in these outcomes led them to provide wage increases to their hourly workforce and leadership team, all while reducing labor costs by 12% in the first quarter of 2024. Units produced per labor hour also improved from 18.6 to 22.0 in the first quarter of 2024, marking an 18.2% improvement.