Project Overview

Performance Results

Situation

One of the top wholesale health food supply chain distributors and suppliers in the USA found itself struggling with an age-old business dilemma during peak season: how could they improve production efficiency to meet supply demands under the challenges of labor management?

A surge in demand necessitated this wholesale giant to hire temporary employees, while production leadership struggled with making effective business decisions and lacked the essential problem-solving tools. This scenario led to suboptimal performance and limited their capacity to respond adequately to market conditions.

Ready to tackle the issue head-on, the company approached POWERS for a short 10-week intervention aimed at rapidly enhancing their production leadership’s skills and capabilities to navigate this critical juncture in their business cycle.

Analysis

This respected supply chain player in the food industry found itself facing a critical juncture marked by challenges in managing its workforce and making its production process efficient during the busiest time of the year. As customer demand surged, they had to bring in temporary workers, which complicated their operations. Meanwhile, their leadership team struggled with lacking effective tools for problem-solving and necessary skills. This disconnect between what they aimed for and what they achieved led to less-than-optimal performance and difficulties in quickly adapting to market changes.

Central to these problems was the absence of a good system for managing operations. Shockingly, 97% of the tools needed for this system were either missing or outdated. This impacted various areas, such as keeping employees engaged, working together to solve problems, and assigning tasks properly.

The issue extended to the way supervisors interacted with their teams. Instead of dedicating enough time to guiding and training their employees, supervisors spent less than an hour on these crucial tasks. This caused an imbalance and affected the smooth running of the production process.

This imbalance also showed up in how workers were allocated to different tasks. Some areas had too many people while others needed more help, but this wasn't managed efficiently. There was also confusion about what defined a "good" day for a supervisor, which made it hard to establish a clear standard for success.

On top of this, there was often a lack of supervisors on the floor, leading to inconsistent guidance and oversight. When they were around, their methods varied, making it difficult for employees to know what was expected of them. This inconsistency in leadership practices affected the development of skills and overall performance.

In a nutshell, the situation was a mix of complex challenges that ranged from the way the organization was managed to how supervisors interacted with their teams. Addressing these challenges required a smart solution that could improve the overall system, provide better guidance, and help this supply chain giant become more competitive.

- Deficiency in the necessary tools to establish an effective Management Operating

System (MOS). - A staggering 97% of required tools were either absent or in need of upgrading.

- A lack of essential behaviors among supervisors, such as employee engagement,

problem-solving collaboration, and effective delegation. - Supervisors were spending less than an hour per day on supervisory functions,

hindering their ability to guide, coach, and lead their teams effectively.

The Plan:

With a tight 10-week timeframe, POWERS devised a comprehensive plan to expedite the production team's learning curve and position them to sustain their new MOS. The strategy involved several key components:

- Action-Focused Meetings: Revamped daily meetings centered around actionable

steps based on plan variances. - Process Improvement Training: Provided on-the-floor training for supervisors in

understanding the business through a balanced single-piece flow process. - Labor Efficiency Enhancement: Enabled supervisors to identify overstaffed lines

based on product type and improve efficiency by reallocating employees. - Leadership Development: Clarified leadership responsibilities at different levels and

instilled problem-solving skills to eliminate productivity barriers. - Supervisory Skill Enhancement: Allowed supervisors to concentrate on improving their

supervisory skills to foster departmental efficiency.

The Solution:

To address the intricate challenges faced by this food distribution company, POWERS devised a comprehensive solution that aimed to transform the organization's operational landscape and empower its workforce. The core of this solution was to establish a clear path for improvement that aligned intentions with practical outcomes, fostering a culture of collaboration, accountability, and continuous enhancement.

Empowering Frontline Leaders

Recognizing the need for a change in approach, POWERS' plan focused on cultivating Frontline Leaders as proactive problem-solvers. Instead of just reacting to issues, these leaders would step into the role of people managers who anticipate and mitigate challenges. This shift would empower them to take ownership of outcomes, promoting a proactive and accountable management style.

Metrics That Matter

A crucial part of the solution was to assign specific metrics to Frontline Leaders that would emphasize accountability. This shift encouraged leaders to track and manage performance indicators directly linked to success. By establishing clear performance markers, leaders were motivated to drive improvements in areas like uptime, productivity, and employee engagement.

Collaborative Approach

POWERS' solution facilitated collaboration across all tiers of management to support Frontline Leaders in addressing day-to-day challenges. This approach helped bridge the gap between leadership levels, ensuring that a collective effort was made to overcome obstacles and maintain the organization's momentum.

Clear Roles and Responsibilities

To eliminate ambiguities and streamline operations, the solution established precise roles and responsibilities for each level of leadership. This clarity ensured that everyone understood their part in the organization's success, minimizing confusion and enabling smoother decision-making.

Ownership and Immediate Action

One of the cornerstones of the solution was shifting the responsibility of problem-solving to Frontline Managers. Rather than passing issues up the chain of command, leaders were empowered to take charge of finding solutions and driving immediate action. This approach nurtured a culture of ownership and proactive management.

Skill Enhancement and Training

To address skills gaps, POWERS introduced a comprehensive mechanism to assess and enhance technician skills. This involved establishing mechanic skills baselines and integrating these benchmarks into planning and scheduling. By providing targeted training and allocating tasks more efficiently, the organization aimed to minimize downtime and operational hiccups.

In essence, the solution crafted by POWERS was designed to instill a sense of ownership, accountability, and proactivity within the wholesaler’s workforce. By redefining roles, enhancing skills, and empowering Frontline Leaders, the organization aimed to establish a more efficient, collaborative, and responsive operational framework that would not only address immediate challenges but also lay the foundation for sustained growth and excellence.

Results:

This wholesale food distributor’s visionary collaboration with POWERS marked a remarkable 10-week journey that ignited a substantial transformation in their operational landscape. The comprehensive intervention yielded an array of remarkable outcomes, effectively bridging the gap between challenges and triumphs.

In the span of a mere 10 weeks, the concerted efforts resulted in a series of quantifiable triumphs, underscoring the power of strategic intervention:

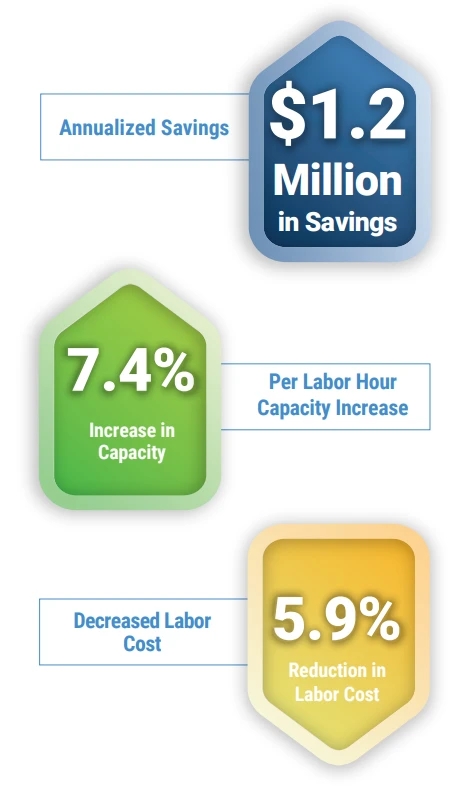

- Enhanced Efficiency: A 7.4% improvement in pounds per labor hour, reflecting enhanced production efficiency. In the intricate dance of supply chain management, every fraction of a percent translates into increased capacity, enabling this company to meet burgeoning demands without compromising quality or speed.

- Optimized Costs: A 5.9% reduction in labor cost per pound, demonstrating optimized labor management. When it comes to supply chain operations, cost optimization is the bedrock of sustainability and competitiveness. This achievement affords the company the financial flexibility to invest in innovation, growth, and weather market fluctuations.

- Substantial Savings: An impressive $1.25 million in annualized savings, attributed to increased productivity and streamlined processes. In the dynamic realm of supply chains, savings cascade across the organization, infusing capital into vital endeavors and fueling strategic expansion.

- Exceeding Expectations: Surpassing expectations, the achieved results were 56% above the initially identified savings opportunity. This leap showcases not only the immediate efficacy of the collaboration but also the inherent capacity for unprecedented growth within the company’s supply chain ecosystem.

This wholesale food distributor’s partnership with POWERS led to a significant enhancement in production efficiency, labor management, and overall operational effectiveness. The intervention not only enabled them to respond effectively to market demands but also solidified their commitment to continuous improvement and sustainable growth.